Introduction

The industrial landscape is undergoing a profound transformation, driven by technological advancements that are reshaping operational paradigms. Among the most impactful innovations is the widespread adoption of drone-backed inspection services. Once a niche application, drones are now indispensable tools, fundamentally changing how industries approach safety, efficiency, and asset management.

-

“Drone Inspection isn’t merely a technological upgrade; It’s a strategic imperative, empowering industries to achieve unparalleled safety, efficiency, and data precision in asset management.”

Traditional inspection methods often involve significant risks to personnel, extensive scaffolding, lengthy shutdowns, and limited access to critical areas. Drones, equipped with high-resolution cameras, thermal sensors, and specialized non-destructive testing (NDT) payloads, are dismantling these barriers, offering a safer, faster, and more data-rich alternative. This shift is not just about technology; it’s about a complete re-imagining of industrial dynamics, moving from reactive maintenance to proactive, data-driven intelligence.

Let’s explore some key industrial use cases and observe how drones are changing the game:

Chimney & Stack Inspections: Soaring Beyond Heights and Hazards

Industrial chimneys and stacks are often massive, aging structures crucial to operations but extremely dangerous to inspect manually. Traditionally, this required elaborate scaffolding, rope access teams, or expensive aerial lifts, leading to significant downtime and inherent risks.

The Drone Advantage: Drones can quickly ascend and circumnavigate these colossal structures, capturing high-definition visual imagery of the entire exterior. For critical integrity checks, drones equipped with ultrasonic thickness gauging (UTG) sensors can precisely measure wall thickness remotely, identifying corrosion, erosion, or structural fatigue without direct human contact.

Case Study Insight (Hypothetical): A large power plant faced a mandated annual inspection of its 150-meter-tall concrete chimney. Historically, this involved a 3-week shutdown for scaffolding erection and human inspection. By deploying a drone equipped with visual and UTG capabilities, the plant completed the external inspection in just two days, requiring only a brief operational slowdown, not a full shutdown. The drone identified subtle hairline cracks and localized thinning in a flue section that would have been costly to detect manually, enabling proactive repairs and saving an estimated $500,000 in potential downtime and scaffolding costs. This shift allowed their maintenance schedule to be optimized, proving the drone’s value in both cost-efficiency and early defect detection.

Boiler Inspections: Penetrating the Heart of the Plant

Boilers are the workhorses of many industrial facilities, but their internal inspection is notoriously challenging due to confined spaces, extreme temperatures, and often hazardous residues. Human entry requires extensive cool-down periods, ventilation, and complex confined space entry procedures.

The Drone Advantage: Specialized, small drones, often with protective cages, can fly into the internal chambers of boilers, capturing detailed visual and thermal data of tubes, refractory, and other components. They can navigate tight spaces, illuminating dark areas and providing high-resolution imagery that reveals signs of corrosion, blockages, or wear.

Case Study Insight (Hypothetical): A chemical manufacturing unit experienced frequent unplanned outages due to boiler tube failures. Their traditional internal inspections were limited to visual checks during annual shutdowns. By integrating caged drones for pre-shutdown preliminary inspections, they managed to identify several bulging and corroded tubes during a minor planned maintenance window, well before they became critical failures. The drone provided clear visuals, allowing the maintenance team to order specific replacement parts in advance, drastically reducing the subsequent shutdown duration by five days and preventing two major unplanned outages within the year. This proactive approach significantly improved their Overall Equipment Effectiveness (OEE).

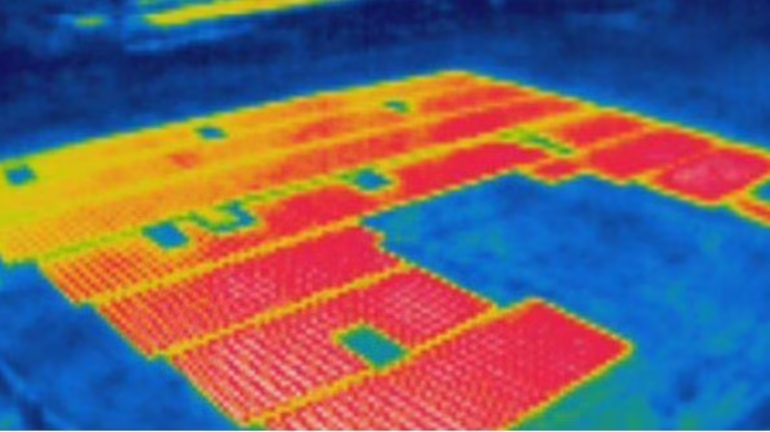

Thermography of Switchyards and Solar Plants: Detecting Invisible Threats

Electrical and solar infrastructure operates at high temperatures, and hot spots often signal impending failures, energy loss, or safety hazards. Detecting these anomalies manually across vast areas or high-voltage equipment is time-consuming and dangerous.

The Drone Advantage: Drones equipped with high-resolution thermal cameras can rapidly scan vast expanses of switchyards and solar arrays. They can identify subtle temperature differentials in transformers, circuit breakers, busbars, and solar panels, pinpointing overheating components or underperforming cells. This non-contact method ensures the safety of personnel while providing comprehensive thermal mapping.

Case Study Insight (Hypothetical): A large solar farm was struggling with underperformance. Manual thermal gun inspections were slow and inconsistent. By implementing weekly drone thermography, they quickly identified over 200 “hot panels” and string failures across their 50-acre site. The drone data precisely located the faulty panels, enabling targeted repairs by a small ground crew. This led to a 7% increase in energy generation within a month, demonstrating how drones can turn invisible energy losses into tangible operational gains, dramatically improving return on investment. Similarly, a regional electricity transmission company used drones to thermally inspect their critical switchyards annually. During one such inspection, the drone identified an abnormal hot spot on a high-voltage disconnect switch that was not visible to the naked eye. This early detection allowed for a scheduled replacement, preventing a catastrophic outage that could have affected thousands of consumers and caused millions in damages.

The Changing Dynamics

The integration of drone-backed inspections is ushering in several dynamic shifts across industries:

Elevated Safety Standards: The paramount benefit is the drastic reduction in human exposure to hazardous, high-altitude, or confined environments.

Enhanced Efficiency & Cost Savings: Faster inspections, reduced downtime, and the elimination of expensive traditional methods lead to significant operational savings.

Data-Driven Decision Making: High-quality visual, thermal, and sensor data provide unprecedented insights, enabling predictive maintenance strategies and informed asset management.

Improved Compliance & Risk Mitigation: Proactive identification of issues ensures adherence to regulatory standards and minimizes the likelihood of critical failures.

Increased Asset Lifespan & Performance: Regular, detailed inspections allow for timely interventions, extending the operational life of critical infrastructure and optimizing performance.

In essence, drone technology is not just augmenting traditional inspection methods; it’s fundamentally reshaping them, driving a new era of proactive, intelligent, and safe industrial operations. Companies that embrace these capabilities are not just staying competitive; they are leading the way in operational excellence and responsible asset management.

Frequently Asked Questions (FAQs)

1. What are the main advantages of using drones for inspections?

The primary benefits are enhanced safety, speed, and cost savings. Drones eliminate the need for workers to be in dangerous, hard-to-reach locations. They can inspect large areas in a fraction of the time. This drastically reduces downtime and labor costs.

2. What industries are already using drone inspections?

Drones are being used across many sectors. The energy sector uses them for inspecting oil rigs and solar farms. In construction, they monitor site progress and survey buildings. They are also essential for surveying infrastructure like bridges, dams, and pipelines.

3. How do drones inspect more accurately than traditional methods?

Drones use high-resolution cameras and advanced sensors. Examples include thermal imaging and LiDAR. They capture detailed, objective data. This allows for precise analysis. It also creates a permanent digital record for future reference.

4. What kind of data can drones collect during an inspection?

Drones can capture much more than just video. They collect high-resolution images and 4K video. They can also use thermal sensors to find heat anomalies. Multispectral sensors can assess crop health. LiDAR creates highly accurate 3D models.

5. What are the safety and regulatory considerations for drone inspections?

Safety is paramount. In India, regulations require drone registration and pilot certification. No-fly zones exist around airports and key installations. A thorough risk assessment is essential before any flight.

Your Challenge: See the Possibilities

The era of dangerous, time-consuming inspections is over. Drones offer a safer, smarter, and more efficient way to manage your assets. The shift is not just about technology. It’s about a new way of thinking.

What is the biggest inspection challenge at your facility today? Are you still relying on scaffolding or manual labor? How could a drone solve that problem for you?

Share your thoughts and challenges in the comments. Let’s explore this new future together.

#DroneInspection #IndustrialSafety #EHS #AssetIntegrity #PredictiveMaintenance #SmartManufacturing #Innovation #DigitalTransformation #Industry40 #SafetyFirst #Manufacturing #EnergySector #ChemicalIndustry #OilAndGas #Gujarat #Technology #InspectionTech #RiskMitigation