IIoT Backed Predictive Maintenance Solutions

Earthpit Monitoring Solution

Overview

Digital Edge offers Vadict Earth Pit Monitoring Solution.

Ground resistance should be kept as low as possible to minimize the risk of equipment failure from fault current. Poor grounding also results in poor power quality. Due to aging, moisture, corrosion, and other factors, ground resistance increases. Therefore, a time-based ground resistance measurement is performed to monitor healthiness of ground rods.

An IoT sensor for earthpit monitoring has been developed by Vadict. Integrated with IIoT platform, the sensor provides real-time earthpit resistance values.

Stakeless technique for resistance measurement

Traditional resistance measurement technique with stakes is time consuming and labour intensive. The present technique provides earth ground loop resistance without using stakes. Therefore, it is a fast and easy technique.

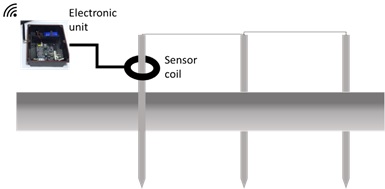

The earthpit sensor used in this technique is made up of two different coils, and it is placed around the ground rod. The primary injection coil injects a small excitation ac voltage and secondary coil measures resulting current flow in earthing loop. Since stakes are not used, the present technique will work for closed circuits. A schematic of measurement system is presented above.

Earthpit sensor unit comprises of two major parts, viz. sensor magnetic coil and electronics processing unit. Both parts are connected through a cable, conduit, and gland arrangement. Electronics processing unit is enclosed with an IP67 plastic enclosure and named as Vadict IoT Sensor unit.

Sensor installation

The Earthpit sensor coil is an apparatus to be used along with Vadict IoT Sensor Device for measuring effective resistance of Earthpits using “stakeless” method described in the previous section. The Earthpit sensor coil is mounted on earthing bars near the earth-pits. The data is collected from these sensors at a pre-programmed and configurable regular interval, which is then sent to the nearby router device wirelessly.

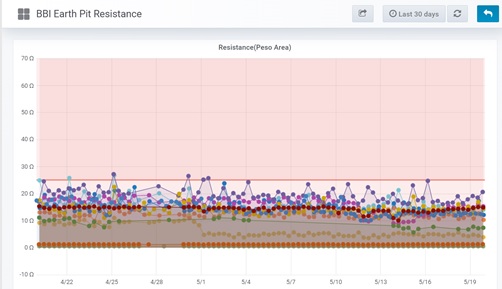

Data presentation on dashboard

Real-time resistance values measured at pre-defined interval are presented on the dashboard. Above plot presents trends of measured resistance for different earthpits.

Alerts can be set for anamolies in impedence levels. The alerts can be sent by mail or SMS.

Get a Quote

An earthpit is an underground excavation used for grounding electrical systems. It helps dissipate electrical fault currents and lightning strikes safely into the earth.

Earthpit monitoring is crucial to ensure the safety and effectiveness of your grounding system. Here’s why:

Prevents electrical hazards: Improperly functioning earthpits can lead to electrical shocks, equipment damage, and even fires.

Ensures regulatory compliance: Most regions have regulations mandating periodic earthpit testing and maintenance. Monitoring helps ensure compliance.

Optimizes performance: Monitoring allows you to identify potential issues early and take corrective actions before the earthpit malfunctions.

Extends lifespan: Proper monitoring and maintenance can significantly extend the lifespan of your earthpit.

Commonly monitored parameters include:

Earth pit resistance: Measures the ability of the earthpit to conduct electricity.

Soil moisture content: Dry soil can reduce the effectiveness of the earthpit.

Electrode (earthing rod) condition: Monitoring helps detect corrosion or damage to the grounding electrode.

Temperature: Excessive temperature can indicate overloading or potential problems.

This technology is valuable for anyone with a grounding system, including:

- Commercial and industrial facilities

- Telecommunication companies

- Data centers

- Hospitals

- Government buildings