IIoT Backed Predictive Maintenance Solutions

Electrical Signature Analysis Solution

Overview

Digital Edge offers Vadict ESA Solution for predictive maintenance use-cases for critical rotary equipment.

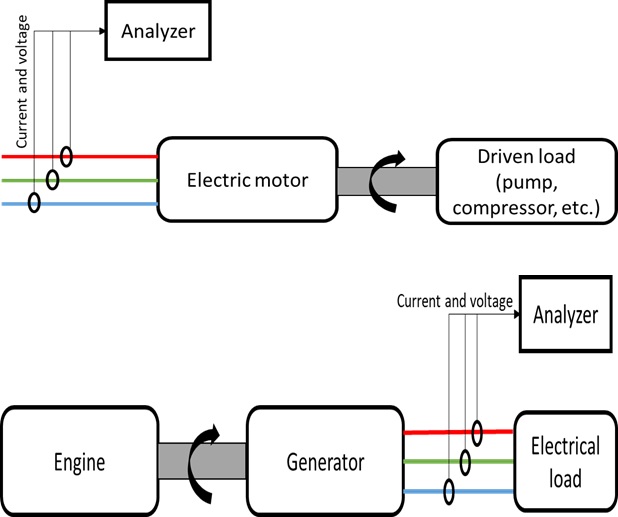

Electrical signature analysis (ESA) is a non-intrusive condition monitoring technique for electrical equipment. Using this technique, conditions of supply, motor, and driven load (pump, compressor, etc.) are evaluated.

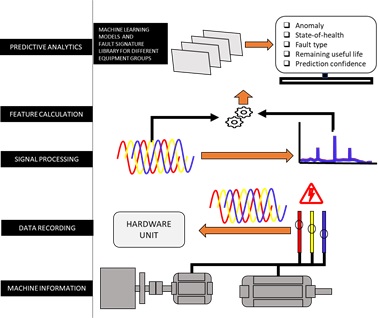

Current and voltage waveforms are captured at motor control centers (MCC/PMCC) and processed for further analysis. Key parameters are transmitted to an IIoT platform (hosted on-premise or on cloud) for predictive analysis for RUL and fault-type identification. Selected parameters are presented on Vadict IIoT dashboard with historical trends. Based on the universal standards or site recommendation, the threshold limits are set for alert and alarm indication.

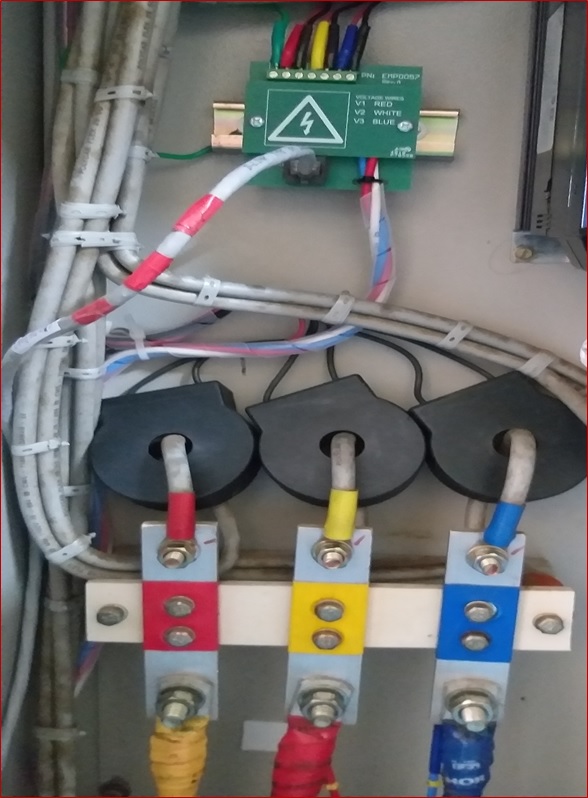

Sensor Installation

Electrical signature analysis is a non-intrusive technique where current and voltage measurements are performed installed at MCC/PMCC centers. Current transformers (CTs) are installed at power cables carrying current to motors. CTs are selected based on the cable size, current rating and frequency response. In case of multiple parallel power cables, a CT can be installed at any one of the cables, and a factor can be set at software that multiplied with measured current.

For voltage rating up to 1000 V RMS, voltage leads can be directly connected with hardware unit. Whereas, secondary of potential transformers (could be existing measurement PTs) to be connected to hardware unit.

Principle and data processing

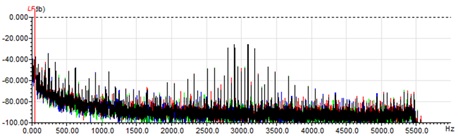

Basic principle of ESA is that any variation in mechanical/electrical conditions cause change in current and voltage signals. Such changes are monitored by processing of captured signals. Time-domain signals are first converted into frequency domain via FFT algorithm. Faults such as rotor bar breakage, static and dynamic eccentricity, etc., are identified from the amplitude of different fault frequencies.

Equipment information such as bearing models, number of rotor bars and stator slots, etc., are required for the accurate and detailed analysis. Measurement is performed manually or by the automated scheduler (with a pre-defined interval or based on equipment status).

Data points are captured manually or by the automated scheduler (with a pre-defined interval or based on equipment status). Total data recording time is ~50 seconds. It is an on-line approach, i.e., testing is performed when machine is in running condition.

There are several advantages to using ESA:

Predictive maintenance: Identify potential equipment issues early on, allowing you to schedule repairs proactively and minimize downtime.

Improved reliability: By addressing problems before they escalate, you can ensure the smooth operation of your equipment.

Reduced maintenance costs: Proactive maintenance is typically less expensive than corrective maintenance after a breakdown occurs.

Enhanced safety: Early detection of electrical problems can help prevent accidents and equipment failures.

ESA can detect a variety of electrical issues, including:

- Bearing wear

- Misalignment

- Imbalance

- Winding faults

- Loose connections

- Overheating

ESA systems typically use sensors attached to equipment that monitor various electrical parameters like current, voltage, and power factor. The collected data is then analyzed using specialized software to identify anomalies and potential problems.

The frequency of ESA testing depends on the criticality of the equipment and the operating environment. Critical equipment might require regular monitoring, while less critical machinery could be tested at defined intervals.

ESA is valuable for a wide range of industries that rely on electrical equipment, including:

- Manufacturing

- Oil & Gas

- Power generation

- Facilities management

- Transportation

Use-Case ESA of VFD motor

Electrical data captured at very high sample rate processed through electronic unit placed near feeders. The unit consists of analog front-end, multiplexer and micro-controller for processing analog data. Data samples then transmitted to gateway via Ethernet for further processing. Below is the list of calculated and estimated parameters,

Time domain data converted into frequency domain using fast Fourier transform. Data quality check logic used to verify the correctness of data for further processing. In case of large variation in speed and load, electrical data vary significantly, and may results in false positives, if processed. After data sanity check, state-of-health, fault type identification, and RUL estimation is performed.

Fault Detection

ESA solution is very useful as in identification of following issues:Data presentation on dashboard

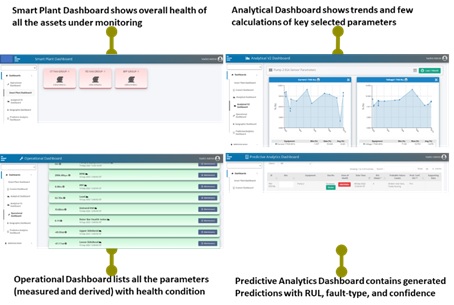

Vadict IIoT platform shows ESA parameters with historical trends. Snapshots of the dashboard with ESA parameters are shown below

Advantages of ESA

Generally, offline or static motor tests are performed for condition assessment of insulation and rotor bars. Such tests are time consuming and require putting motor out of operation. Some tests like grawler test for rotor bars provide only pass/fail results, i.e., non-trendable values.

Following are the advantages of online ESA technique over offline tests: