Introduction

In the dynamic world of manufacturing, ensuring a safe, healthy, and environmentally compliant workplace is paramount. Traditional EHS (Environment, Health, and Safety) management often relies on periodic checks, manual data collection, and reactive measures. However, with the advent of the Industrial Internet of Things (IIoT), a new era of proactive, data-driven EHS is emerging, promising unprecedented levels of safety, efficiency, and compliance.

“In manufacturing, IoT shifts EHS from hindsight to foresight, giving us real-time visibility and control to prevent incidents before they occur.”

Enter IoT: The Game Changer for EHS

IoT, or the Internet of Things, refers to a network of physical objects embedded with sensors, software, and other technologies for the purpose of connecting and exchanging data with other devices and systems over the internet. When applied to EHS in manufacturing, IoT enables:

Real-time Data Collection: Sensors continuously monitor critical parameters.

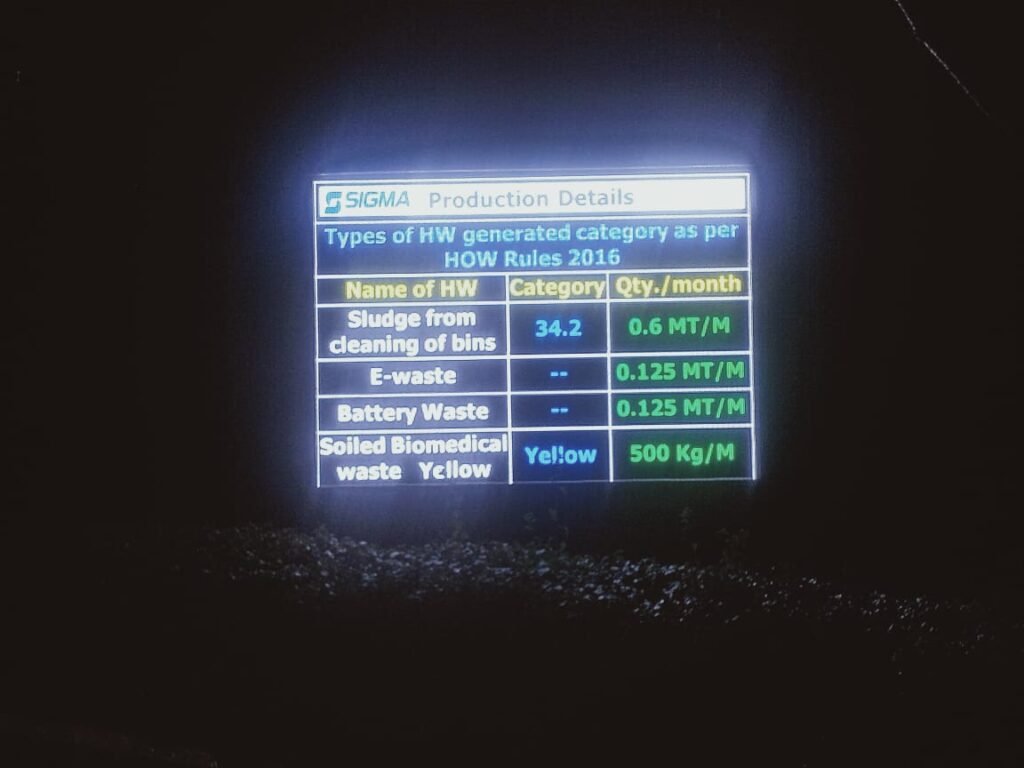

Instant Visibility: Data is streamed to dashboards, providing immediate insights. It can be IoT-Enabled TV (Samsung 138 cm (55 inches) Crystal 4K Vista Pro Ultra HD Smart TV) or LED Display Board.

Predictive Capabilities: Analytics identify potential risks before they escalate.

Automated Alerts: Notifications are triggered for deviations or emergencies.

This shift from reactive to proactive EHS management is not just an improvement; it’s a fundamental transformation.

Key Use Cases and Benefits of IoT in Manufacturing EHS:

- Real-Time Environmental Monitoring:

- Enhanced Worker Safety with Wearables:

- Asset Integrity & Predictive Safety:

- Environmental Compliance & Automated Reporting:

- Improved Emergency Response:

Why Now is the Time for IoT in EHS

The manufacturing industry is increasingly embracing Industry 4.0 principles, where connectivity, data, and automation drive operational excellence. EHS cannot be left behind. Deploying IoT solutions within EHS is not just about compliance; it’s about:

- Reducing Operational Costs: By preventing incidents, optimizing maintenance, and streamlining reporting.

- Boosting Productivity: Through reduced downtime and a healthier, safer workforce.

- Enhancing Brand Reputation: Demonstrating a strong commitment to employee well-being and environmental stewardship.

- Gaining a Competitive Edge: By operating a safer, more efficient, and more resilient plant.

Frequently Asked Questions (FAQs)

1. What is IoT in the context of EHS?

IoT, or the Internet of Things, refers to a network of physical devices. These devices have sensors and software. They collect and exchange data. For EHS, they monitor real-time conditions. This includes air quality and equipment status.

2. What are some specific examples of IoT devices for EHS?

Many devices are used. Wearable sensors track a worker’s heart rate or location. Smart helmets can detect impacts. Gas detectors send instant alerts. Smart sensors on machinery detect vibrations and temperature.

3. How does IoT help prevent accidents?

IoT shifts EHS from reactive to proactive. It continuously monitors for hazards. The system can send an immediate alert if a gas leak occurs. This gives teams time to respond. It prevents incidents before they occur.

4. What kind of data can IoT sensors collect?

IoT sensors collect a wide range of data. They monitor environmental conditions. This includes temperature, humidity, and noise levels. They can also track hazardous chemicals. This provides a complete picture of the workplace.

5. Is it difficult to integrate IoT devices with existing plant systems?

Modern IoT solutions are designed for integration. They use standard communication protocols. They can often be added to existing machines. This allows for a fast and efficient implementation. They work with your current infrastructure.

The Future of EHS is Connected

IoT is not just a technology. It is a new way of managing safety. It gives you real-time visibility and control. This empowers you to prevent incidents. It creates a safer, smarter work environment.

Consider your plant’s most critical EHS risk. Is it a specific machine, or a process? How could real-time data from an IoT sensor help you manage that risk?

Ready to build a safer, smarter future for your manufacturing plant?

At Digital Edge, we specialize in designing and implementing comprehensive IoT-backed EHS solutions tailored for manufacturing plants. We help you integrate these smart technologies seamlessly, transforming your safety protocols from reactive to predictive.

Connect with us to explore how IoT can revolutionize your EHS strategy. Share your thoughts in the comments. Let’s discuss a more connected future for your plant.

#IoT #EHS #Manufacturing #IndustrialSafety #SmartFactory #Industry40 #DigitalTransformation #PredictiveMaintenance #RealTimeData #WorkplaceSafety #EnvironmentalCompliance #Automation #SafetySolutions #IIoT #Manufacturing

qq8822 Jul 14, 2025 at 04:56 am

Tried my luck on QQ8822. Nothing groundbreaking, but it does what it says on the tin. Good if you’re just looking for something simple and straightforward, ya know?: qq8822