The future of manufacturing is data-driven, and achieving true Operational Excellence requires ditching manual logs for real-time intelligence. CIPL’s LUMI SIMPLIFY OEE is a powerful, low-cost solution designed to streamline your operations and unleash the full potential of your plant. This wireless OEE monitoring system integrates seamlessly with advanced Andon Solutions to deliver immediate, actionable insights across your entire shop floor.

Overall Equipment Effectiveness (OEE) is the most crucial metric for measuring manufacturing productivity. Our IIoT-backed device, automates the capture of the three core factors of OEE, ensuring 100% Data Accuracy and eliminating human errors.

IIoT Backed Solutions

OEE Solution

| OEE Factor | SIMPLIFY OEE Functionality | Key Data Points |

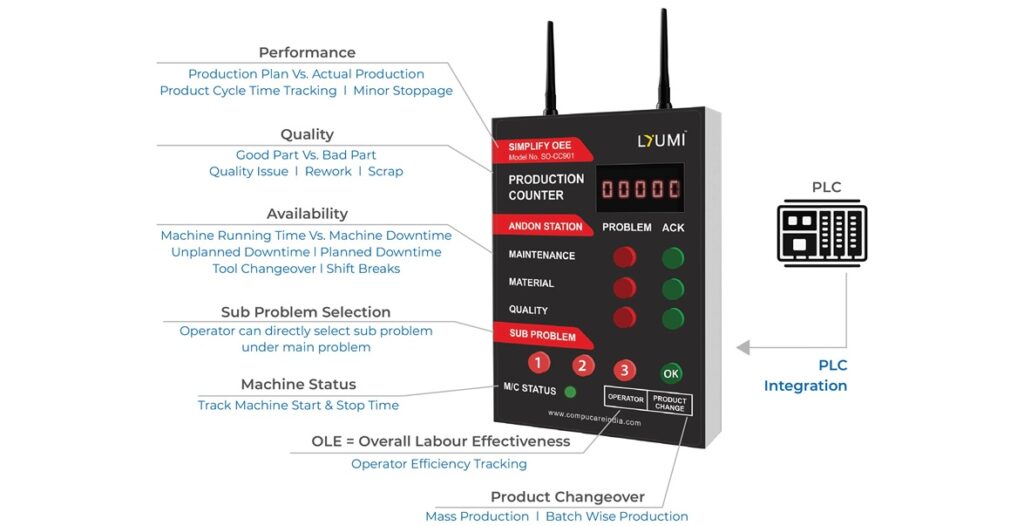

| Availability | Tracks machine state automatically via PLC / SENSOR or manually. | Machine Running Time Vs. Machine Downtime, Unplanned Downtime, Planned Downtime, Shift Breaks, Tool Changeover. |

| Performance | Monitors actual output against planned cycles. | Production Plan Vs. Actual Production, Product Cycle Time Tracking, Minor Stoppage. |

| Quality | Captures and categorizes all losses and defects. | Good Part Vs. Bad Part, Quality Issue, Rework, and Scrap. |

Simplify OEE

is a hybrid solution consisting of wireless hardware device and application software monitoring OEE. It is designed to seamlessly capture three components of OEE, i.e. Availability, Quality & Performance. This helps streamline Overall Equipment Effectiveness (OEE) tracking and improvement in discrete manufacturing, not so much in process manufacturing.

Focus on Ease of Use:

Simplifies OEE calculations, making it accessible to a wider audience within a company.

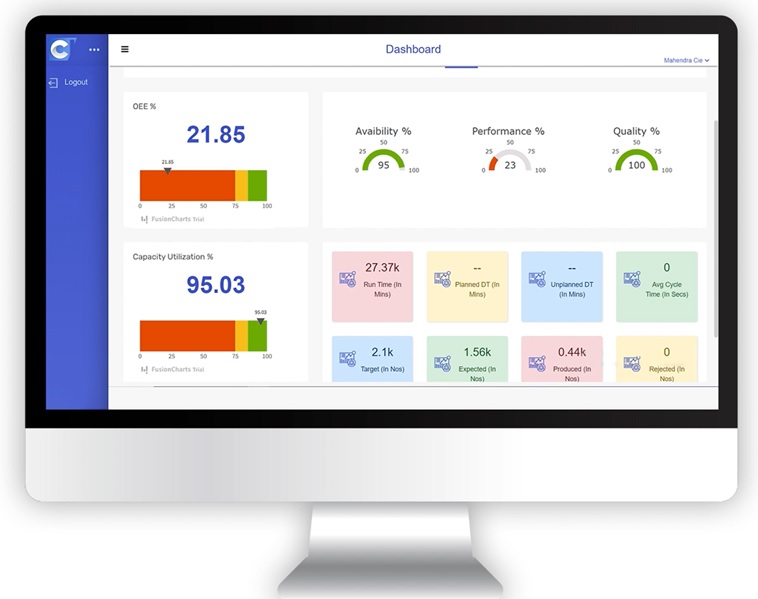

Offers real-time data on OEE metrics, providing immediate insights into production line performance.

Data-Driven Decision Making:

Enables identification of bottlenecks and inefficiencies in the production process.

Provides insights to optimize workflows and make informed decisions for overall efficiency improvement.

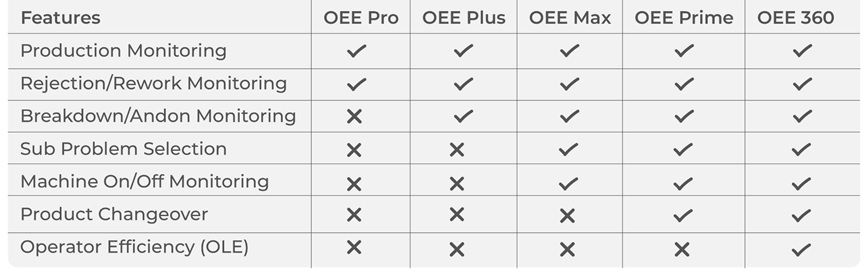

OEE Solution Matrix

Overall, Simplify OEE helps manufacturers gain real-time visibility into their production processes, identify areas for improvement, and make data-driven decisions to optimize efficiency and maximize output.

Beyond OEE: Tracking Labor and Process

OLE (Overall Labour Effectiveness): The system provides Operator Efficiency Tracking, monitoring the performance and labor ROI of your workforce.

Product Changeover: Effortlessly manage both Mass Production and Batch-wise Production.

Data Integration: Our solution is ready for Integration with ERP/SAP/NAV systems, breaking down data silos for comprehensive Business Intelligence.

Instant Action: The Power of the Andon System

A modern Andon System is your digital call-for-help, ensuring quick problem detection and response times. Our integrated ANDON STATION immediately converts shop floor issues into actionable data:

Immediate Alerts:

Operators use the dedicated buttons (MAINTENANCE, MATERIAL, QUALITY) to signal a fault, which lights up the Tower Light and appears instantly on the Shopfloor Visual.

Root Cause Analysis:

The Sub Problem Selection feature allows the operator to select a specific issue under the main problem, enabling highly accurate root cause analysis.

Visual Factory:

The system provides real-time visualization of OEE, Target, Actual, and Efficiency (%).

Data-Backed Resolution:

The system tracks the Problem Solution Duration, providing managers with the data needed to eliminate systemic inefficiencies.

Your Turn to Achieve World-Class OEE!

You’ve seen the data. SIMPLIFY OEE and the integrated Andon System are the foundation for your Smart Manufacturing future. Stop letting Operational Inefficiencies cost you profit.

What is the biggest roadblock preventing your plant from hitting that 85% World-Class OEE benchmark? Is it Workforce Efficiency, Maintenance & Repairs, or simply the lack of Real-Time Data?

Technical Edge & Business Benefits

Specifications & Connectivity

The SIMPLIFY OEE device is built for the demanding industrial environment, operating with Working Voltage: DC9V-14V and across ambient temperatures.

Connectivity: Features a Communication Type: Wi-Fi/Ethernet.

Input: Includes dedicated inputs for Andon Input – 3 and Production Input – 1.

Capacity: Offers a Record Capacity: 16,000 transactions.

Ideal For: The solution is versatile for CNC Machine, Press Machine, Injection Moulding, Robots, and all types of Assembly Lines.

Improved Production Monitoring:

Integrates with production monitoring systems, giving visibility into machine utilization, cycle times, and production counts.

Includes Andon functionality, which utilizes visual and audible alerts for operators to quickly signal production issues. This facilitates faster response times and reduces downtime.

Key Benefits of Digital Transformation

Reduced Human Errors: Data entry is Real-time & Automatic.

Reduced Downtime: Quick response from the Andon system and Predictive Maintenance insights minimize Equipment Failures.

Greater Transparency: Provides complete real-time visibility for all stakeholders.

Increased Output: Leads to the Preservation of Time & Resources with Enhanced Output.

Enhanced Team Motivation: Motivate Your Production Teams with Goals displayed live on the shop floor.

Get a Quote

Using sensors and other automation techniques, we can bring data of old machine on dashboard.

The specific sensors used will depend on the machines and processes being monitored, e.g. optical, temperature, pressure sensors, etc.

You can start by identifying your specific needs and approach us for a customized solution to meet those needs.

The ROI for an IIoT solution for OEE can be significant. By improving OEE, you can increase production output, reduce costs, and improve profitability.

Security is a critical concern for any IIoT application. Effy is installed on on-premise server and it has strong security features in place, such as encryption and authentication.

The top challenges are Data Collection & Analysis, Equipment Downtime, and Integration Challenges. Our solution is specifically a Low Cost Automation system, directly addressing cost and complexity while providing a unified platform for accurate and reliable data.

It calculates Availability based on Machine Running Time Vs. Machine Downtime. Performance is based on comparing Actual Production to the Production Plan and tracking Minor Stoppage. Quality is determined by comparing Good Part Vs. Bad Part and accounting for Scrap and Rework.

The Andon System enables operators to signal Problem and identify the Sub Problem immediately. This real-time data allows the management team to conduct Root Cause Analysis and implement solutions before minor stoppages become major breakdowns, fundamentally shifting from reactive to proactive maintenance.

The system generates a comprehensive suite of reports, including OEE Report, Shift Wise Overall Production Report, Production Overall Summary, Rejection Summary, and detailed Breakdown Detail. These reports provide data for data-driven decision-making.