Introduction

India’s manufacturing sector is on an ambitious growth trajectory, fueled by initiatives like “Make in India” and production-linked incentive (PLI) schemes. To truly compete on a global scale and achieve higher levels of efficiency, quality, and resilience, Indian manufacturers are increasingly turning to advanced technologies. Among the most transformative are Digital Twins and Simulation.

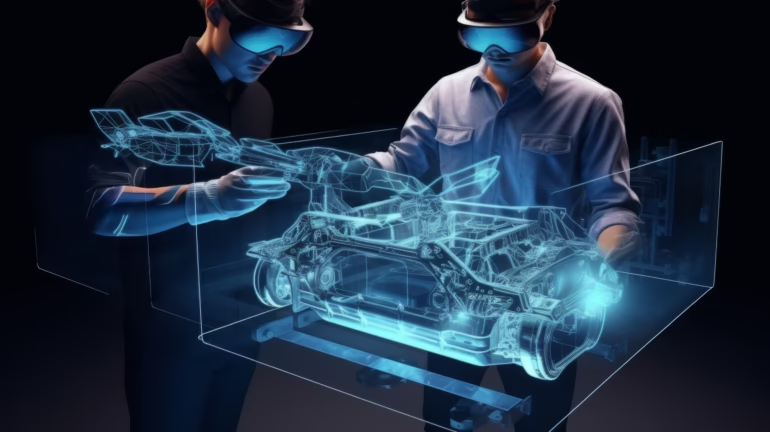

These aren’t just buzzwords; they are powerful tools that create a virtual replica of a physical asset, process, or even an entire factory. This “digital twin” is continuously updated with real-time data from sensors and other sources, allowing for dynamic simulation, analysis, and optimization without disrupting actual operations.

“Digital twins are not just virtual replicas; they are living, breathing digital counterparts that empower manufacturers to predict, optimize, and innovate, transforming every aspect from design to real-time production and maintenance.”

What are Digital Twins and Simulation?

A Digital Twin is a virtual model designed to accurately reflect a physical object, process, or system. It’s a living, breathing digital counterpart that receives real-time data from its physical twin, enabling continuous monitoring, analysis, and prediction of its behavior.

Simulation, in this context, is the ability to run “what-if” scenarios on the digital twin. This allows manufacturers to test changes, optimize processes, and foresee potential issues in a risk-free virtual environment before implementing them in the real world.

Why are Digital Twins and Simulation Critical for Indian Manufacturing?

The Indian manufacturing landscape, with its diverse industries and complex supply chains, stands to gain immensely from these technologies:

- Enhanced Operational Efficiency and Productivity:

- Superior Predictive Maintenance:

- Accelerated Product Development and Quality Improvement:

- Resilient Supply Chain Optimization:

- Improved Workforce Training and Safety:

- Sustainability Leadership:

Challenges and the Road Ahead for India

While the benefits are clear, adoption in India faces hurdles such as:

- Initial Investment Costs: Digital twin deployments can be expensive, limiting access for smaller and medium enterprises (SMEs).

- Data Interoperability: Integrating data from disparate systems across the factory floor can be complex.

- Skilled Workforce: A scarcity of professionals with expertise in digital twin technologies, AI, and data analytics.

- Awareness and Value Proposition: A need for a clearer understanding among stakeholders about the tangible ROI of digital twins.

Despite these challenges, the momentum is building. Leading Indian companies like Ola Electric and Reliance Industries are already leveraging digital twins for complex factory planning and optimization. System integrators like TCS and Tech Mahindra are also developing industrial AI and digital twin solutions, supporting the widespread adoption.

The future of Indian manufacturing is undoubtedly digital. By strategically investing in digital twin and simulation technologies and by fostering a digitally skilled workforce, India’s manufacturers can unlock unprecedented levels of efficiency, innovation, and global competitiveness, contributing significantly to the nation’s economic aspirations.

Frequently Asked Questions (FAQs)

1. What is a digital twin?

A digital twin is a virtual replica of a physical object or system. It can be a single machine or an entire factory floor. It connects to the real-world counterpart. This allows for real-time monitoring and analysis.

2. How does simulation help in a manufacturing plant?

Simulation allows you to test scenarios virtually. You can optimize a production line layout. You can test new equipment without disrupting operations. This reduces the risk of expensive errors. It saves you significant time and money.

3. What are the key benefits for Indian manufacturing?

The benefits are substantial. Digital twins reduce unplanned downtime. They help identify bottlenecks and increase efficiency. They also enable predictive maintenance. This prevents costly breakdowns. It boosts overall productivity and helps meet global standards.

4. Are these technologies only for large companies?

No, that’s a common myth. The technology is now more accessible. There are scalable, cloud-based solutions. Small and medium-sized enterprises (SMEs) can also implement them. The key is to start with a specific problem.

5. How can my company start its journey?

Begin by identifying a single use case. It could be optimizing a critical machine. You could also improve a specific process. Partner with a vendor. They can help you with the implementation and data integration.

Your Blueprint for Success

The manufacturing landscape is changing rapidly. Digital twins and simulation are not just buzzwords. They are powerful tools for gaining a competitive edge. They provide the foresight you need to innovate.

What is the biggest challenge on your plant floor today? Is it equipment downtime or process inefficiency? How could a virtual replica of your operations help you solve it?

Share your thoughts and questions below. Let’s create the blueprint for a smarter, more productive future.

Is your manufacturing operation ready to virtually transform its future?

#DigitalTwin #Simulation #Manufacturing #IndiaManufacturing #SmartFactory #Industry40 #MakeInIndia #PredictiveMaintenance #SupplyChainOptimization #WorkforceTraining #Sustainability #OperationalExcellence #DigitalTransformation #IIoT #AI #Innovation #IndianIndustry